Questo articolo spiega come si può far funzionare fino a 6 estrusori con una normalissima scheda che ha due driver per estrusori.

Un ringraziamento speciale a angelos del forum reprap Italia.

Prima cosa bisogna acquistare una scheda arduino da 8 relè. Verificare che sia optoisolata e funzionate a 5v.

Esempio:

![SainSmart-8-Channel-DC-5V-Relay-01[1]](/wp-content/uploads/2016/03/SainSmart-8-Channel-DC-5V-Relay-011-300x174.jpg)

Una volta fatto questo abilitiamo nel firmware MK4duo la funzione MKR6, per prima cosa diciamo al FW che abbiamo 6 estrusori:

/***********************************************************************

************************** Extruders number ***************************

***********************************************************************/

// This defines the number of extruder real or virtual

#define EXTRUDERS 6

Poi definiamo che abbiamo 2 driver per gli estrusori:

// This defines the number of Driver extruder you have and use

#define DRIVER_EXTRUDERS 2

A questo punto andiamo in Configuration_Feature.h e abilitiamo MKR4:

/***********************************************************************

************************* Multiextruder MKR6 **************************

***********************************************************************

* *

* Setting for more extruder width relay system *

* This is new system for 6 extruder width 2 driver and 6 relay. *

* See Configuration_pins.h for pin command relay *

* *

* Uncomment MKR6 to enable this feature *

* *

* Uncomment INVERTED_RELE_PINS if your relay switches with GND *

***********************************************************************/

#define MKR6

//#define INVERTED_RELE_PINS

/***********************************************************************/

C’è anche la possibilità di invertire il segnale per far scattare i relè se per caso si attivano con livello basso…

Dobbiamo anche dire al Firmware che pur avendo 6 estrusori però abbiamo un solo Hotend, quindi sempre in Configuration_Feature.h abilitiamo Singlenozzle:

/***********************************************************************

**************************** Single nozzle ****************************

***********************************************************************

* *

* This is used for single nozzle and multiple extrusion configuration *

* *

* Uncomment SINGLENOZZLE to enable this feature *

* *

***********************************************************************/

#define SINGLENOZZLE

/***********************************************************************/

Tutto questo lo possiamo fare in maniera semplice e rapida con il configuratore on line che trovate qui sul blog.

Ora per concludere la parte Firmware andiamo in Configuration_Pins.h e diciamo al Firmware quali sono i pin che servono per far scattare i relè. I pin da settare sono EX1_CHOICE_PIN e EX2_CHOICE_PIN:

#define EX1_CHOICE_PIN 5

#define EX2_CHOICE_PIN 6

Questi 2 pin sono un esempio, ma cambiano da scheda in scheda. Per la Ramps 1.4 si possono usare i pin per i servo lasciando il pin 11 per un eventuale servo bed level.

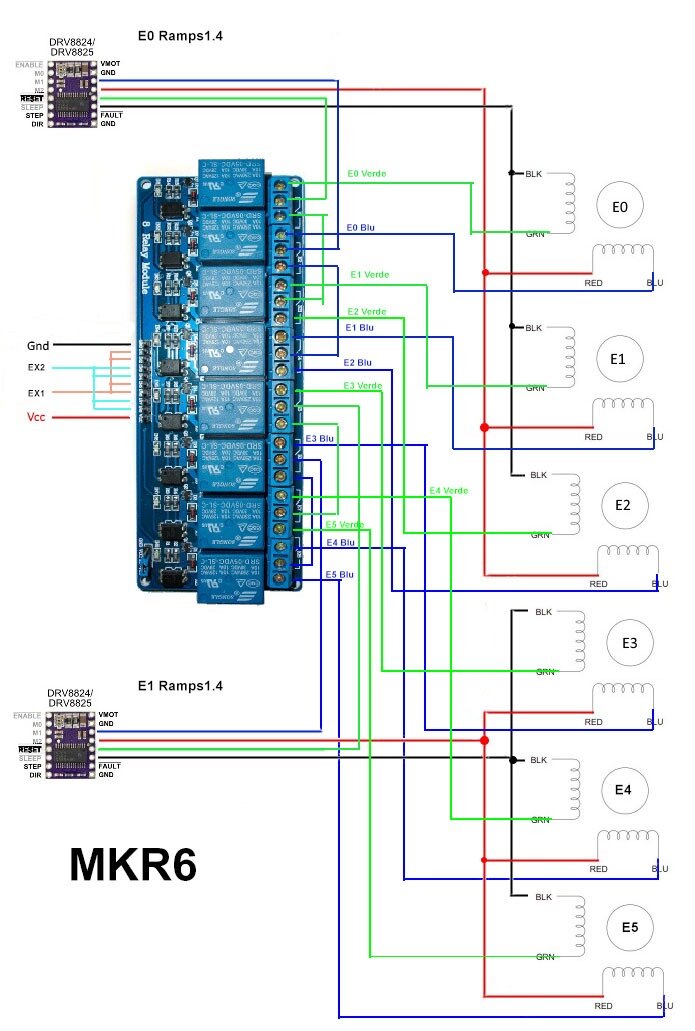

Ora passiamo al cablaggio, prendiamo i 4 fili che escono dal driver E0 e quelli di E1 e li colleghiamo in questa maniera:

Come vedete è abbastanza semplice. Il nero che esce dal driver lo colleghiamo in parallelo su tutti i cavi neri dei vostri 4 motori, stessa cosa facciamo per il rosso. Il nero e il rosso sono l’uscita A1 e B1 del driver, quindi 1 di una coppia e l’altro dell’altra coppia.

Mentre A2 il verde e B2 il blu li andiamo a mettere sul centrale dei due primi relè. I Normalmente Chiusi dei due primi relè li andiamo a collegare al verde e blu del primo motore che sarebbe E0, in questo modo quando i relè sono nella situazione tutti non eccitati il motore che andremo a controllare sarà appunto E0.

I Normalmente Aperti dei due primi relè andranno sui centrali della prossima coppia di relè, mi raccomando non invertite le coppie, mantenete la connessione a due a due…

I Normalmente Chiusi della seconda coppia andranno al verde e blu del secondo motore E1.

I Normalmente Aperti della seconda coppia andranno al verde e blu del terzo motore E2.

La prima coppia serve per commutare tra E0 e seconda coppia.

La seconda coppia serve per commutare tra E1 e E2.

Ripetiamo lo stesso identico concetto sugli altri 4 relè collegati però con il driver E1 per cosi collegare i motori di E3, E4 e E5.

I relè vanno alimentati con una 5v fissa, poi hanno degli ingressi per farli commutare, in questo caso visto che dovranno commutare a coppie dovremmo collegarli tra loro l’in 1 e 2 con in 5 e 6, l’in 3 e 4 con in 7 e 8. Poi dobbiamo portare i 2 pin scelti per farli scattare EX1_CHOICE_PIN e EX2_CHOICE_PIN.

Fatto tutto ciò possiamo alimentare la nostra scheda e dopo aver compilato e scaricato il fw passiamo alla fase di test.

Se abbiamo fatto tutto come si deve dovremmo avere questo risultato: Se ci colleghiamo con Host i relè dovrebbero rimanere tutti nello stato di quiete, ma se passiamo da E0 a E1 dovremmo sentire commutare la prima coppia di relè e anche la terza coppia, ce ne possiamo accorgere dai led che di solito sono montati sulla schedina relè.

Se passiamo da E1 a E2 vedremo scattare anche la seconda coppia di relè insieme alla quarta.

Se passiamo da E2 a E3 vedremo di nuovo tutti i relè tornare nella posizione di quiete, ma verrà usato il driver E1.

Se passiamo da E3 a E4 vedremo scattare di nuovo la prima e la terza coppia, ma usando il driver E1 si muoverà solo il motore di E4.

Se passiamo da E4 a E5 vedremo scattare di nuovo tutti i relé, ma visto che stiamo usando sempre il driver E1 si muoverà solo il motore E5.

A questo punto possiamo provare il tutto. disabilitiamo il controllo di temperatura con il comando M302 P1, questo fa in modo che possiamo estrudere anche se la temperatura dell’hotend non è al di sopra del minimo…

Proviamo a estrudere con ogni singolo estrusore, sentirete i relè commutare ogni qualvolta cambiate estrusore.

MagoKimbra.